Understanding multiaxis milling configurations is essential for industries requiring precise and complex machining operations. Leichman, as one of the leading 5 axis CNC machining center manufacturers, offers advanced solutions to meet these demands, particularly in metal processing and machinery production sectors. Their LK-U220 Five-Axis Machining Center 30000rpm Spindle 400x650x265mm Travel exemplifies the flexibility and precision achievable with modern equipment. Designed for high-efficiency production, this five-axis machining system supports diverse manufacturing requirements, allowing engineers and procurement specialists to optimize workflow while maintaining consistent quality.

Common Multiaxis Configurations

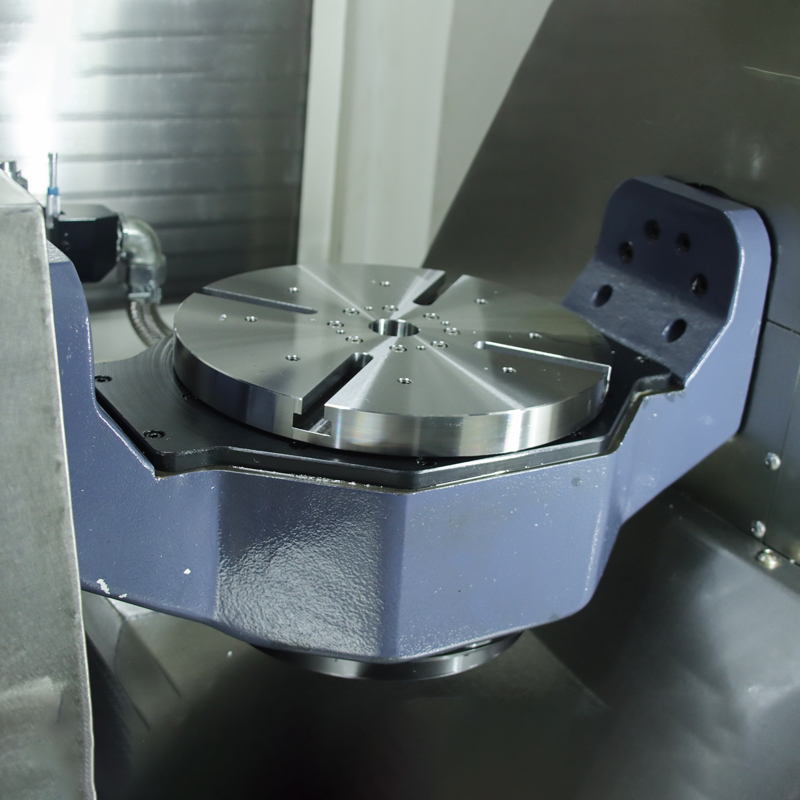

Multiaxis milling machines typically feature three to five axes, with configurations adapted to the complexity of parts. Standard models include 3-axis mills with XYZ linear movements, 4-axis machines adding rotation along one additional axis, and full 5-axis systems combining two rotary axes with three linear movements. As a leading provider among 5 axis CNC machining center manufacturers, Leichman emphasizes machines capable of handling intricate geometries and reducing setup times, enhancing throughput for factories and international trade partners. The LK-U220 five-axis center delivers +110° A-axis rotation and 360° C-axis movement, providing unmatched flexibility for diverse milling tasks.

Advantages of Five-Axis Machining

Using a five axis machining system allows simultaneous movement along multiple axes, improving surface finish, reducing manual setups, and supporting complex components. Leichman ensures their machines, like the LK-U220, feature a 30000rpm NBT30 spindle, 7.5kW power, and a 16-tool servo magazine with 4-second tool change, optimizing production cycles. Their solutions cater to EPC contractors, industrial equipment distributors, and metal fabrication facilities requiring reliable, high-performance equipment. This approach minimizes inventory pressure while delivering precise and repeatable results across different industrial applications.

Conclusion

Selecting the right multiaxis milling machine configuration depends on the specific production requirements and part complexity. Leichman’s offerings demonstrate how 5-axis solutions integrate flexibility, high-speed spindles, and precision control. With XYZ travel of 400x650x265mm and ±0.008mm positioning accuracy, the LK-U220 Five-Axis Machining Center addresses the demands of international trade, mechanical equipment agencies, and metal processing industries. They combine tailored solutions with proactive after-sales support, helping clients optimize operations while ensuring consistent quality and efficiency.