When companies begin exploring options for ordering custom metal components, they often seek practical guidance on specifications, feasibility, and supplier capabilities. Working with a provider like Dingmetal helps many teams navigate these early decisions, since they operate as a China metal parts manufacturer with experience supporting engineering-driven projects. In the early stage, purchasers and engineers typically clarify materials, tolerances, structural requirements, and expected production volumes. This preparation ensures that communication with a custom metal parts supplier becomes more efficient and reduces the likelihood of design revisions later.

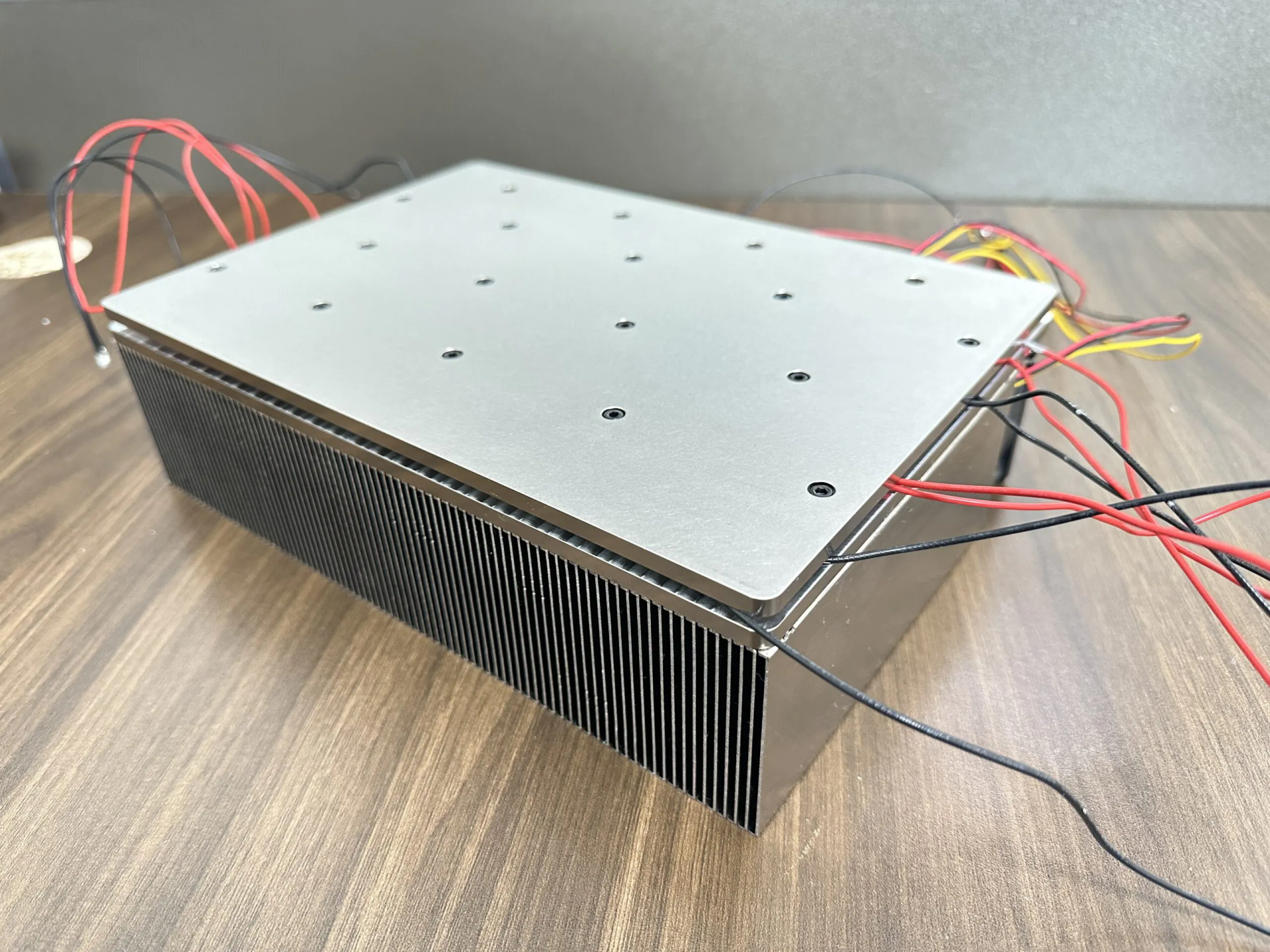

At the same time, some projects involve thermal control requirements. In these cases, understanding the basic structure of Thermoelectric Cooler Assemblies (TECA) is helpful. TECA units rely on Peltier-based solid-state cooling, combining thermoelectric modules with heat sinks, fans, or cold plates. Although they are not the core product in every custom metal project, knowing their functional principles allows teams to evaluate whether the surrounding metal parts must accommodate additional heat-dissipation structures.

Selecting Capabilities That Match Engineering Needs

Once technical requirements are clear, the next step is evaluating which manufacturing processes align with the project. Teams working with Dingmetal, acting as a China metal parts manufacturer, usually compare CNC machining, die casting, stamping, sheet-metal forming, or forging based on structural demands. This stage is not only about choosing a process but also about confirming the supplier’s depth of expertise, quality systems, and ability to manage prototype-to-production transitions.

A dependable custom metal parts supplier typically supports rapid sampling, stable tolerance control, and surface-finishing options that match application needs in electronics, automotive modules, or heat-management components. In projects involving TECA integration, metal brackets, housings, or cold-plate interfaces must maintain thermal contact reliability. Understanding these constraints helps engineers design parts that remain stable under temperature cycling and operational loads.

Coordinating Production, Quality, and Practical Lead Times

When buyers move from design approval to production planning, coordination between engineering and manufacturing becomes essential. Companies communicate expected batch sizes, inspection standards, and packaging needs to ensure smooth processes. Because Dingmetal operates with structured quality management and consistent delivery practices, they can support predictable timelines while fulfilling the role of a China metal parts manufacturer.

For purchasers, the most practical approach is verifying that the chosen custom metal parts supplier offers traceable quality documentation, controlled machining processes, and clear communication regarding project updates. If the application involves TECA-related enclosures or mechanical frames, dimensional accuracy and heat-path consistency must be maintained across the entire batch. These considerations prevent performance variations during integration into larger thermal-management systems.

Conclusion: Coordinating Requirements for Successful Custom Metal Parts Orders

Effective ordering of custom components requires attention to design clarity, manufacturing capability, and communication throughout the project. Working with Dingmetal as a custom metal parts supplier gives engineering teams structured support, whether the parts are general structural components or elements that must operate alongside TECA-based thermal solutions. Their role as a China metal parts manufacturer allows them to meet demands for precision, consistent quality, and suitable lead times. By preparing accurate specifications and understanding application needs—including potential thermal-control considerations—companies can ensure that each custom metal part aligns with performance expectations and long-term reliability.