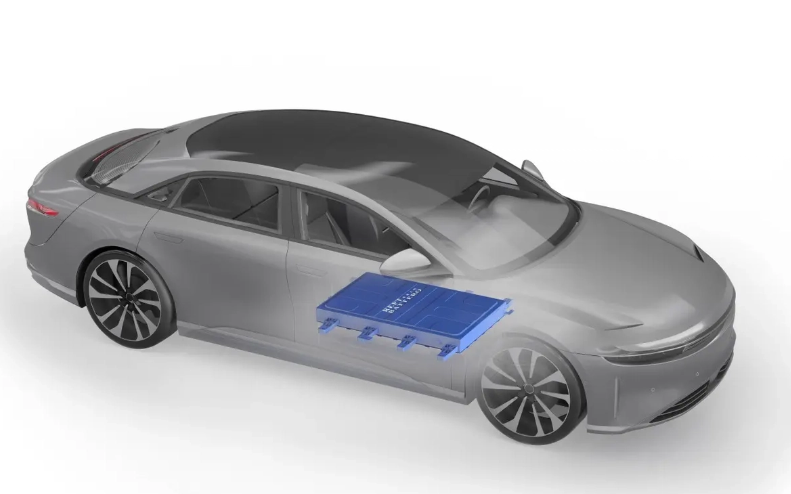

Innovation in electric vehicle batteries is shaping a more sustainable energy landscape, and REPT BATTERO plays a key role in this transformation. Recognized among lithium ion battery manufacturers, they focus on designing PHEV and REEV battery systems that extend electric range, enable fast charging, and maintain high safety standards across all driving conditions. Their technology addresses the needs of automakers, energy storage integrators, and investors who are looking for durable, efficient, and environmentally conscious battery solutions. By combining performance with long-term sustainability, REPT BATTERO demonstrates how industry-leading practices can integrate circular economy principles into modern battery production.

Embracing Recycling and Remanufacturing

Recycling and remanufacturing are emerging as crucial trends in li-ion battery manufacturing. REPT BATTERO actively develops processes to recover valuable materials from used batteries, which reduces waste and limits reliance on newly mined resources. Their approach includes evaluating battery components for potential reuse, refurbishing cells, and ensuring remanufactured units meet stringent performance standards. Such initiatives not only contribute to environmental sustainability but also strengthen supply chain resilience. For hybrid and electric vehicle producers, these practices offer predictable material availability, cost advantages, and alignment with regulatory expectations for responsible battery lifecycle management.

Integrating Sustainability in EV Solutions

Sustainability in battery systems goes beyond recycling; it also involves enhancing energy efficiency and extending the usable life of batteries. REPT BATTERO provides solutions that optimize electric vehicle performance across urban commutes, highway drives, and mixed-use scenarios. Their designs support faster charging times, reduce fuel consumption in hybrid vehicles, and ensure reliability for long-term operation. As a trusted lithium ion battery manufacturer, they combine advanced engineering with rigorous quality control, ensuring that recycled or remanufactured batteries achieve high standards of safety and effectiveness. This integration of sustainability and performance encourages adoption by automakers and energy storage providers who aim to maintain operational excellence while supporting environmental goals.

A Strategic Approach for the Future

Adopting circular practices in li-ion battery manufacturing offers a strategic advantage for companies navigating the evolving energy and transportation sectors. REPT BATTERO leverages technical expertise, robust research and development, and the supply chain support of the Qingshan Group to provide consistent, cost-effective, and innovative solutions. Closed-loop systems, combined with remanufacturing strategies, create a resilient production model capable of supporting large-scale electric vehicle and energy storage deployment. Stakeholders, from investors to integrators, recognize that such sustainable strategies not only reduce environmental impact but also reinforce the reliability and predictability of battery supply chains.

Driving Sustainable Battery Solutions

With growing global emphasis on sustainability, recycling, and efficient production, REPT BATTERO, as a prominent lithium ion battery manufacturer, illustrates how technical innovation and environmental responsibility can coexist. Their focus on closed-loop solutions and remanufactured battery systems ensures that electric vehicles and energy storage platforms remain dependable, cost-effective, and ecologically responsible. By prioritizing circular approaches, they contribute to a future where battery resources are fully optimized, offering a model for long-term industry sustainability.