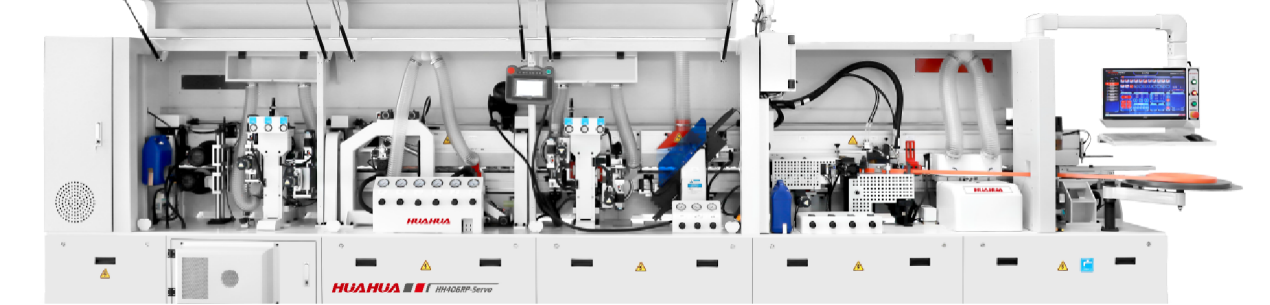

HUAHUA CNC continues to lead the woodworking industry with its innovative HH-406RP model, a state-of-the-art servo edge banding machine designed for optimal performance and user convenience. With features that streamline operations and enhance precision, this machine is perfect for woodworking professionals seeking to improve their edge banding processes.

User-Friendly Computer Screen

The HH-406RP is equipped with a large computer screen that simplifies operation. This intuitive interface provides complete operating instructions, allowing users to navigate the machine effortlessly. Additionally, the single-arm suspension design saves valuable space in the workshop, making it easier to integrate into existing setups. By prioritizing user experience, HUAHUA CNC ensures that operators can focus on their work without unnecessary complications.

Precision with Servo Positioning Plate

One of the standout features of the HH-406RP is its high-precision servo positioning plate. The advanced control of the servo motor guarantees accurate positioning of the panel during the edge banding process. This level of precision is crucial for achieving clean, professional finishes on various materials, making the servo edge banding machine an essential tool for any woodworking operation. The combination of ease of use and precise control allows businesses to enhance productivity while maintaining high-quality standards.

Conclusion

In conclusion, HUAHUA CNC’s HH-406RP servo edge banding machine is a game-changer for woodworking professionals. With its large computer screen, user-friendly interface, and innovative servo positioning plate, this machine is designed to improve efficiency and accuracy in edge banding processes. Investing in the HH-406RP means choosing a reliable solution that enhances productivity and delivers exceptional results, solidifying HUAHUA CNC’s reputation as a leader in the woodworking machinery industry.