The 2026 additive manufacturing event is set to reveal the latest trends in 3D printing technology. TCT Asia, established in 2015, has become a central platform for 3D printing additive manufacturing intelligence in Asia. They aim to provide a full-spectrum understanding of how additive manufacturing can enhance design, engineering, and production processes. Attendees at the Shanghai show (March 17-19, 2026) can expect insights into emerging technologies and practical applications that drive industry growth.

Innovations at a Leading 3D Printer Exhibition China

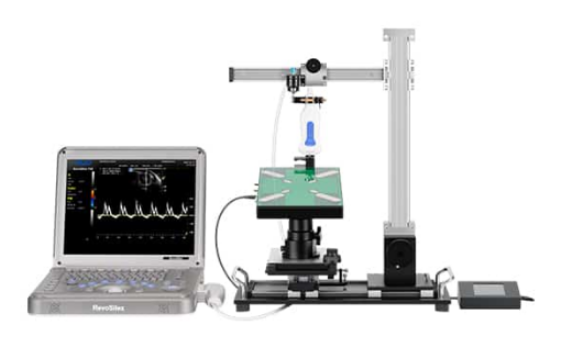

At this 3D printer exhibition China, TCT Asia will showcase over 550 exhibitors across 55,000 square meters, covering the complete additive manufacturing ecosystem. Live demonstrations allow participants to explore the capabilities of new materials, printing processes, and software solutions. They highlight how additive techniques are applied in automotive, aerospace, and medical sectors, illustrating real-world benefits beyond theoretical discussion. For designers and engineers, this exhibition is an invaluable opportunity to evaluate new solutions and adopt them in their own workflows.

Predicted Trends in Additive Manufacturing for 2026

Industry experts anticipate several key trends for 2026. The adoption of high-performance polymers and metal alloys in industrial 3D printer systems is expected to accelerate, enabling lighter and more durable parts for aerospace and automotive applications. Multi-material printing and hybrid manufacturing solutions will gain traction, combining additive and traditional methods for optimized production. Additionally, software-driven process optimization, AI-assisted design, and real-time monitoring will enhance efficiency, reduce waste, and improve consistency across complex production workflows. These trends highlight the growing integration of 3D printing into mainstream manufacturing.

Networking and Knowledge Sharing at Asia’s Additive Manufacturing Event

The best 3D printing events in Asia focus not only on technology but also on meaningful interactions. TCT Asia offers professional conferences, workshops, and networking opportunities, connecting over 35,000 visitors with industry experts. By discussing challenges and sharing insights, participants gain actionable knowledge to optimise additive manufacturing applications. The Shenzhen show (October 14-16, 2026) will continue this tradition, providing additional chances for professionals to engage with the latest developments in the field.

Conclusion: Why TCT Asia Remains a Must-Visit Event

In summary, the 2026 additive manufacturing event at TCT Asia demonstrates the evolution and impact of 3D printing technologies. Through live demos, comprehensive exhibits, and interactive sessions, attendees gain both inspiration and practical takeaways. This 3D printer exhibition China is not only a showcase of technology but a platform for adopting innovative solutions, fostering collaborations, and advancing the industry as a whole. Professionals aiming to stay ahead in additive manufacturing will find TCT Asia an essential destination.