SLA 3D printers have revolutionized the world of additive manufacturing by providing high precision, exceptional detail, and excellent surface finish for various applications. Stereolithography (SLA) utilizes photopolymerization to create three-dimensional objects layer by layer, making SLA resin 3D printers a preferred choice for industries focused on quality and accuracy.

Understanding the Technology Behind SLA 3D Printing

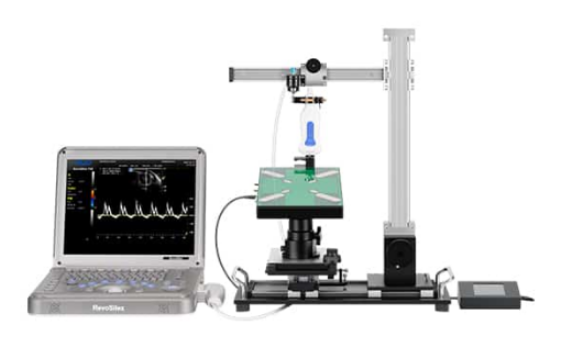

An SLA 3D printer employs a laser beam to selectively cure liquid resin into solid layers, building up an object from the base upwards. This process begins with a digital model, which the printer slices into thin layers. The laser then moves across the resin tank, illuminating specific areas to harden the material. Once a layer is completed, the build platform lowers slightly to prepare for the next layer, and the process repeats. This method results in incredibly detailed prints that exhibit fine features and smooth finishes, making SLA technology ideal for intricate designs.

Applications and Advantages of SLA Resin 3D Printers

SLA resin 3D printers are widely utilized across several industries, including automotive, electronics, and healthcare, due to their ability to produce complex geometries and high-quality prototypes quickly. The speed of design iterations and the reduced material waste make SLA 3D printers cost-effective solutions for businesses looking to optimize their production processes. Furthermore, the variety of resins available allows companies to select materials suited for different applications, whether for functional prototypes or aesthetic models.

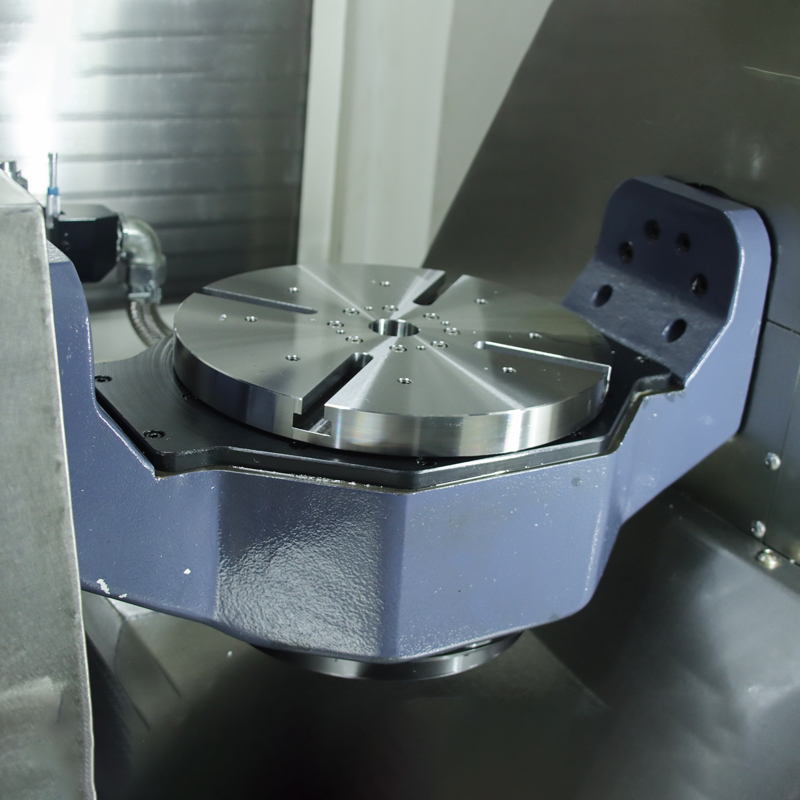

Elevate Your Production with SoonSer’s Smart Series

For companies looking to adopt SLA technology, the SoonSer Smart Series stands out as a reliable and intelligent option. These compact SLA 3D printers deliver industrial-grade precision while accommodating space-constrained environments, making them perfect for businesses seeking powerful prototyping and production capabilities. With features like an easy-to-install build plate, a readily replaceable resin tank, and remote monitoring capabilities, the SoonSer Smart Series simplifies the SLA printing process. By investing in innovative SLA resin 3D printers from SoonSer, businesses can enhance their production capabilities and unlock new opportunities in the competitive landscape of 3D printing.